The construction industry contains many different sectors. No matter the interest, construction professionals often work on all sorts of fascinating projects, from the sky to the seafloor.

While the end result of construction projects is often seen, the underlying construction processes are often more challenging than they look. Products such as rebar and sprayed concrete may not be the most glamorous parts of a project, but they do form an essential component of many construction projects. Let’s explore the world of underground structures, and what makes it challenging and unique in today’s construction blitz.

Underground Construction – The New Frontier

While many cities are building up, there becomes a point in every city’s life that going up is simply insufficient for further development. Consider, for example, cities such as London, with aging public transport infrastructure.

Where a skyscraper can provide a housing solution, transport solutions require approaches that are ground-level or even subterranean. In turn, this leads to planning and development, which must address both commuter convenience, as well as efficient journey times.

With surface-level transport often unfeasible, due to existing structures, such as heritage-listed buildings, underground construction is rapidly becoming the new frontier for rail expansions in modern metros such as London’s Elizabeth Line, or Brisbane’s Cross River Rail project. This is then supported by other construction development, such as underground shopping centres, or even mini-metropolises.

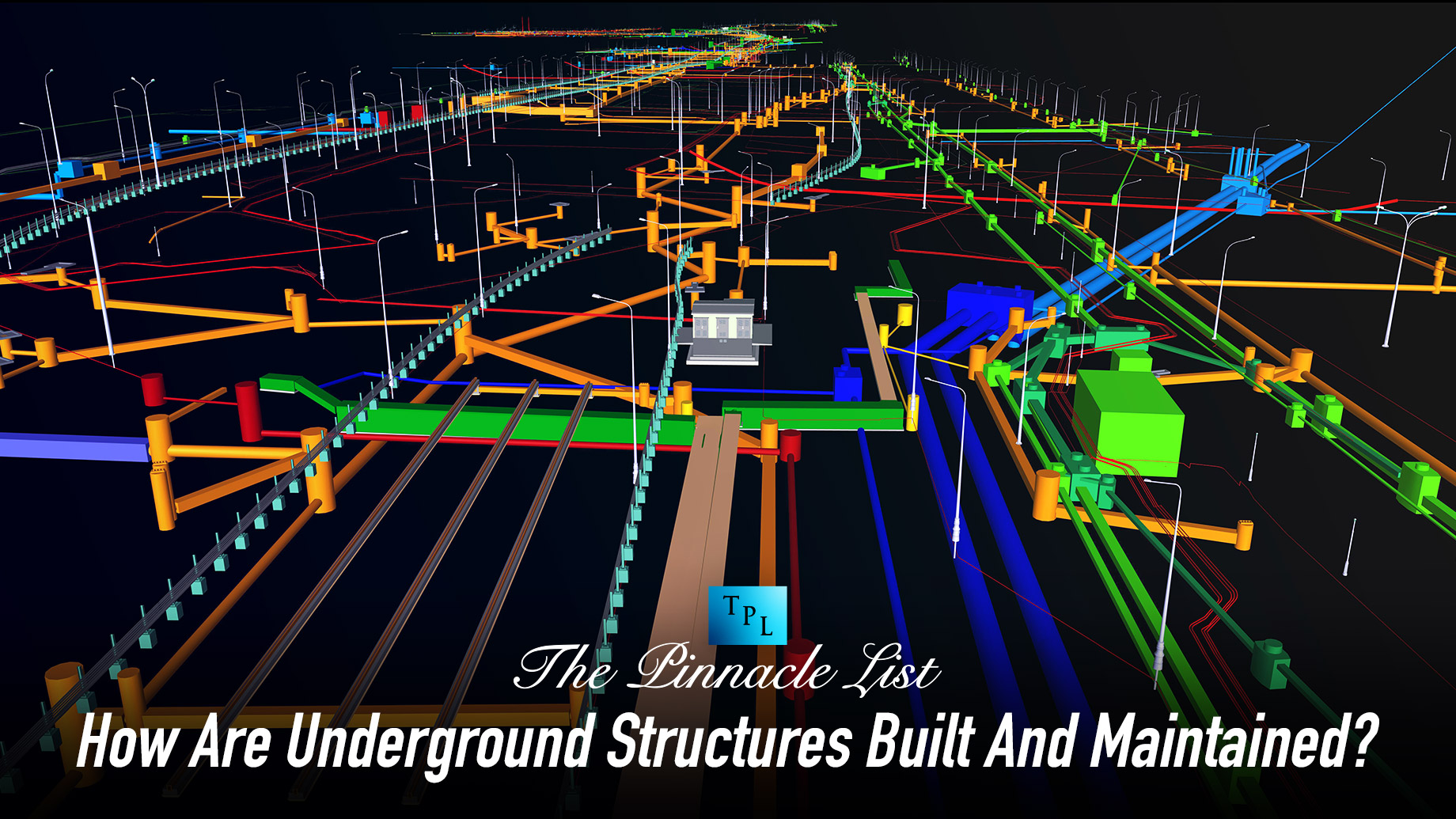

Digging in – Underground Development Methods

When designing underground projects, it’s essential that appropriate development methods are utilized. You don’t simply dig a hole, place a sign on it, and say things are done. Modern design requires modern solutions – and fortunately, the ongoing development of underground construction methods has resulted in techniques that are faster and safer than ever before.

Two common techniques that are used in underground construction are known as the cut-and-cover method, and the use of tunnel boring machines (TBMs). Let’s review how each of these methods works.

Cut and cover construction methods involve the use of excavation machinery to dig a large hole. That’s right – cut and cover digs a hole, and fills it using concrete and pre-fabricated structures. To minimize disruption in urban environments, this may also involve the use of acoustic sheds, to reduce noise emissions from the construction site.

On the other hand, a tunnel boring machine (TBM) involves the use of large machines, that dig their way through underground paths in a highly precise and coordinated routine. Massive cutter heads chew their way through ground conditions that are variable, and line the tunnel they leave with pre-fabricated tunnel walls.

Depending on the scope of the project, these machines can take a significant amount of time to complete a tunnel. In fact, in the development of the Elizabeth line, TBMs operated at an average tunnelling speed of only 38 meters per day, on average. That’s a fraction of the average walking speed of your typical adult!

Different underground structures require different techniques in the planning, development, and implementation of projects. In many cases, the choice is not simply to TBM or not to TBM – depending on your particular local geology, cut and cover may be considered a more appropriate method. Overall, it’s a fascinating form of technology.

Maintenance Mode – Protecting Underground Structures

Once structures are built and reinforced, when the project finally opens, the work’s not simply complete. All projects experience wear and tear – in particular, underground project experience an increased risk of adverse weather events such as flooding.

Fortunately, depending on your use case, there are a number of different solutions in place to ensure that your project lasts well into the future. Equipment such as sprayed concrete can provide an additional surface element to reseal tunnels against the risk of water leaks. Alternatively, improvements to underground infrastructure, such as more efficient lighting and ventilation, can also improve safety and reduce the risk of mould.

Onward! Imagining the Future of Underground Construction

Modern underground structures are transforming the lives of city residents. One example of this is the development of London’s Elizabeth Line, which promises travel savings that can potentially halve the trip time of urban travellers.

These underground projects, while difficult and time-consuming, offer the potential for urban precincts to be reinvigorated, optimized, and reorganized. In fact, underground structural projects are happening all over the world.