The world’s population is increasing by 200,000 people every day, leading to high demands for housing, medical facilities, schools, and transportation infrastructure (to name a few things), so it’s no surprise if contractors become too busy. In this field, labour, efficiency and reliability are most critical. Top-of-the-market equipment is paramount when it comes to pouring concrete, for example. Whether a residential, industrial, commercial, or government project, concrete pumping plays an integral part everywhere. More precisely, concrete pumps come in handy in constructing things like bridges, houses, or anything else.

How does a concrete pump work?

Trucks mix concrete within a revolving drum. It then dispenses it into the hopper, where constant churning prevents concrete from solidifying while in the truck. The hydraulic pumps containing two parallel cylinders come equipped with pistons that move the concrete mass through their backward and forward movements. The pump pulls out the liquid concrete from a hopper to release it through a valve on the required site with the help of an additional hose sometimes. This thorough process comes in handy in building different projects and requires deft handling. For a quick understanding, you can check concretepumpingauckland.co.nz from Auckland, New Zealand.

Of the two cylinders in the systems, one is a material cylinder that helps sucks the concrete from a hopper. On the other hand, the discharge cylinder dispenses the matter at the required location. They work alternately to suck in and out the required volume of the concrete substance.

Types of concrete pumps

Boom pumps and line pumps are the two most common varieties in this. Line pumps or hose pumps produce ground-level concrete and move it through a flexible pipe or hose. The line pumps can be of different types. For instance, stationary line pump systems work through two distinct parts – a pump resting on a small trailer and a separate boom that dispenses concrete from the stationary pump in its precise location. Another variety is a static pump truck attached to a truck bed, such as those designed for concrete pumping. These pumping units mount to a truck and maintain their position but don’t come equipped with booms, so they require additional hoses or other materials to pour concrete.

Lastly, one more option can be a regular mixer pump connected to a truck that carries it straight to the construction site. This concrete truck mixer pump allows for efficient mixing and pumping of cement-based materials. It is particularly effective in any application where the driver can wheel it up near or next to where the concrete has to go.

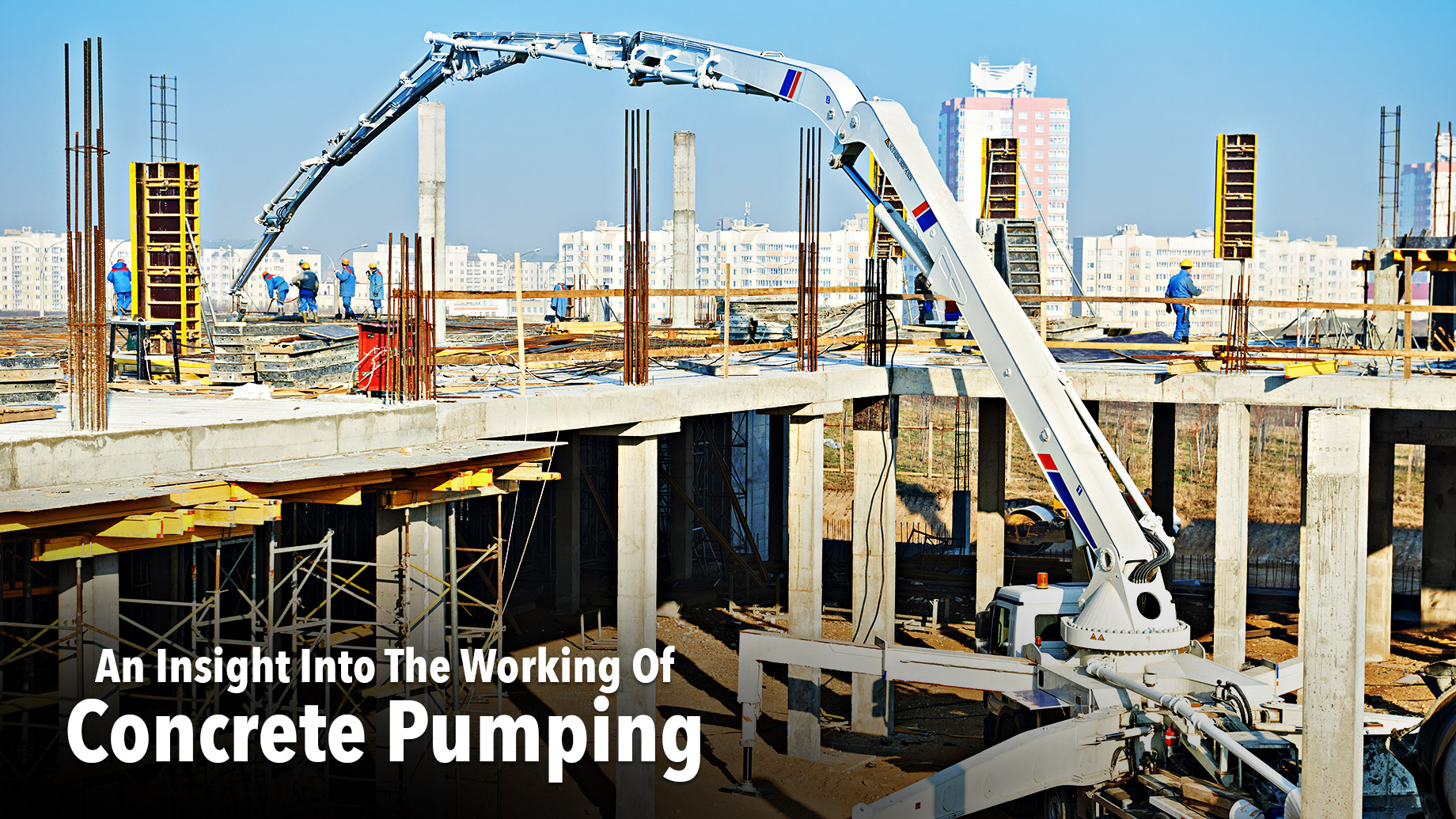

The next main variety is a boom pump. This tool assists with and transports concrete to places that might not be easily accessible. Boom pumps are long, and they use rods, links, arms and other components that enable them to reach higher spaces or other difficult-to-reach areas. A boom pump may be preferable for bigger projects like those with apartment complexes or high rises. There is plenty of practical information to know more about it.

No matter what pumping equipment you need for your construction project, make sure you rely only on the experienced and expert rental service providers and their staff strength. After all, you cannot compromise on quality and experience.