Shipping security is not only about stopping theft. It is also about proving what happens when a carton, tote, trailer, or container changes hands. A seal can turn a vague problem into a clear signal. When a closure is opened, a well chosen seal makes it easier to spot it, document it, and respond before the shipment moves again. Widely used sealing standards describe seals as part of a larger security system, where the seal works best when it is applied correctly and then verified at the next handoff.

This guide keeps the steps simple and practical. You will learn how to match seal style and strength to the shipment type, the closure point, the travel conditions, and the way your team works on a busy day. You will also see why records matter, because verification logs create a reviewable chain of custody when questions come up later. That clarity can reduce disputes, speed up investigations, and help you identify weak points in your process over time.

1. Map The Shipment Type And The Exact Access Point

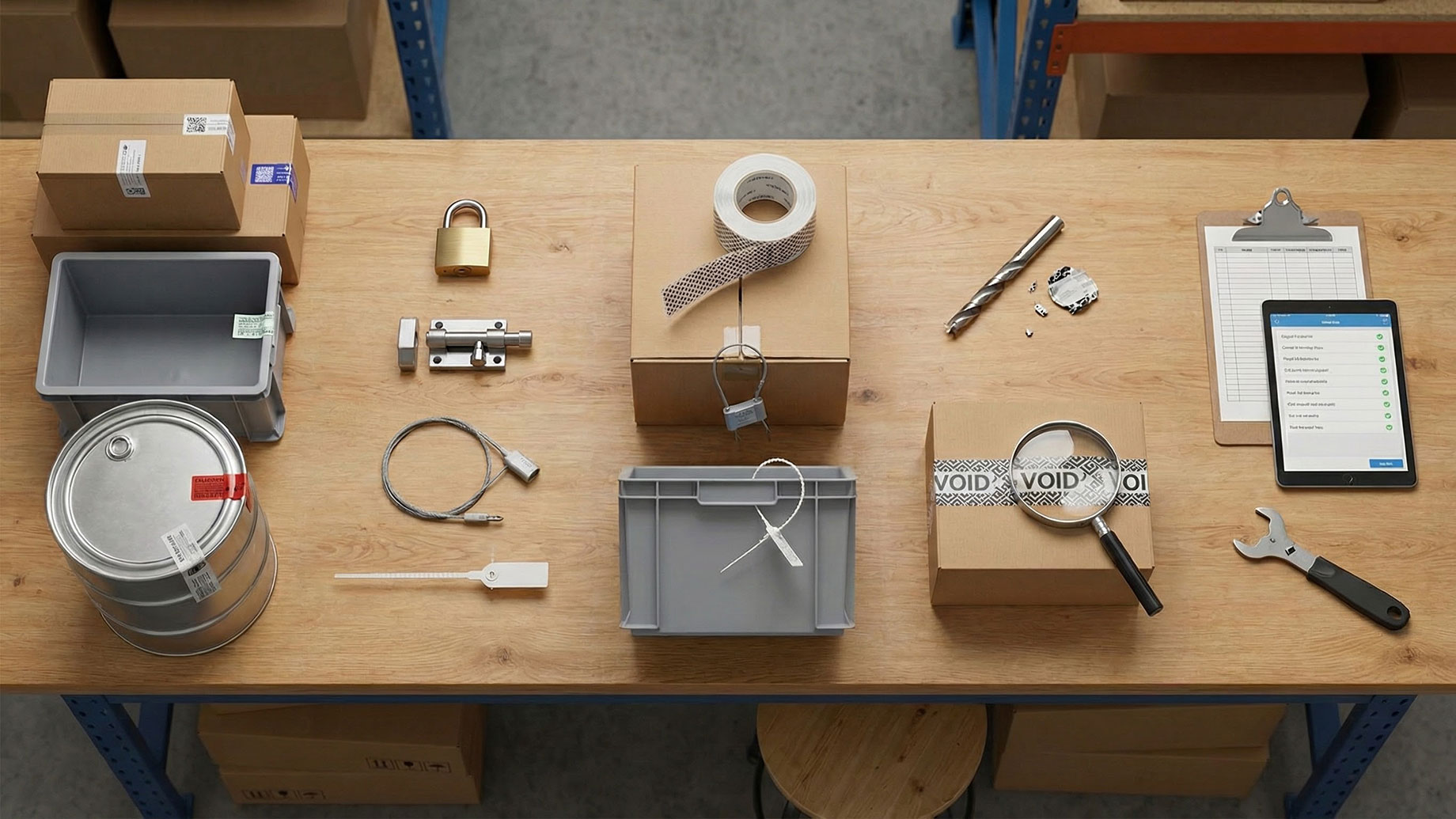

Start by listing your most common shipment types and the single easiest place to open each one. Parcels and cartons have seams, flaps, and corners. Plastic mailers have a top closure and side edges. Totes and hard cases usually have a latch, hasp, or lock hole. Drums and pails can be accessed at the lid, ring, or spout. Trailers and freight containers have door bars, cam keepers, and latch hardware. The seal you choose must fit the real access point. If it does not sit tight, it may be easier to remove, cut, or replace without being noticed during a quick check.

Next, match the access point to how the shipment moves and how often it is handled. A parcel that travels through many hubs needs something receivers can check in seconds, because slow checks often become skipped checks. A pallet load that waits near a dock door may need stronger resistance because access can be easy while nobody is watching. For road freight, many teams use truck seals on door hardware to help confirm whether doors were opened between dispatch and delivery, especially when the route includes stops or yard transfers. The key is to standardize the exact placement so every checker looks at the same point every time.

2. Pick The Right Strength Level Based On Risk

Not every shipment needs the same level of physical strength. Many references describe strength in tiers that separate simple tamper indication from stronger barrier performance. In simple terms, an indicative seal is mainly for showing interference, while a higher strength seal is meant to resist attacks long enough to discourage quick entry. Higher strength seals used on freight doors are commonly tested for resistance to pulling, bending, impact, and cutting forces. Modern requirements also focus on the need for clear evidence of tampering, meaning the seal should show damage in a way that is easier for the user to detect.

A practical way to pick strength is to link it to loss cost and exposure. If goods are low value, travel a short route, and have few handoffs, a basic seal can be enough to provide visibility and reduce disputes. If goods are high value, sensitive, or likely to be targeted, stronger barrier performance can reduce the chance of quick and quiet access. Also consider the likely attack method. If door hardware allows leverage, bending resistance matters. If the risk is quick cutting, shear resistance matters. If the route includes rough handling, impact resistance matters. By matching strength to risk, you avoid both overspending and under protecting.

3. Match Seal Style To Your Materials And Travel Conditions

After you choose a strength level, pick a seal style that works with your packaging and the closure hardware. Mechanical seals are a strong fit for hard access points like latch holes and door hardware. Pull tight seals often work for totes and cases because they thread through a small opening and tighten down, reducing slack. Cable style seals can work for larger latch points and can provide a stronger barrier than light plastic options. Rigid pin style seals are often used for certain freight door setups where the locking point is fixed and strength matters more than flexibility. The best choice is the one that fits the closure point without forcing the user to bend or improvise.

Adhesive solutions are best when you need to secure seams and create a clear opening signal on cartons, mailers, and cases. A common option is tamper evident tape, which is designed to show clear signs of interference when someone tries to peel it back. Many versions leave a visible message or residue on the surface, or they tear in a way that prevents clean resealing. To get consistent results, apply tape to clean and dry surfaces, press firmly across the full length, and place it across the seam so the box cannot be opened without disturbing the tape. This reduces false claims and makes inspection faster for the receiver.

4. Pick Tamper Signals That Customers Notice Right Away

A seal is only useful if people can tell quickly whether it is intact. Look for tamper signals that are hard to hide and hard to reverse. For adhesive seals and labels, that can mean a clear message left behind on the surface after removal, or a material that breaks apart during peeling so it cannot be put back neatly. Many tamper indicating tapes use layered constructions so removal pulls ink or adhesive in a way that reveals an opened pattern. For mechanical seals, tamper evidence can include visible stress marks, deformation, or locking features designed to make quiet manipulation harder. These signals matter most when people inspect quickly under time pressure.

Inspection also depends on identity and records. Choose seals with clear markings and readable numbers, then decide how your team will confirm them at each handoff. The simplest approach is to record the seal number at the time of sealing and verify it at receipt. Photos add extra proof when you need to show condition and placement later, and they can speed up dispute resolution. Standardize the seal location and make the number easy to find, then train receivers to look for both mismatch and physical damage. This is where tamper evident seals support stronger claims handling, because they help you show what was applied, when it was applied, and what condition it was in at inspection.

5. Build A Repeatable Process With The Right Tools And Records

The best sealing program is the one your team will follow on a busy day. Write a short routine that covers receiving seals, storing them, applying them, checking them, and recording results. Strong programs begin before any shipment is sealed. Inspect seals when they arrive, confirm quantities and markings, and control access to unused seals so they do not disappear or get mixed with the wrong batch. Train staff on correct placement and on what normal looks like, because the easiest time to catch a problem is before it leaves the site. A simple routine also helps new staff follow the same steps without guessing.

Tools make consistency easier. Cutters and removal tools help avoid damage to packages during opening and reduce accidental cuts that can look like tampering. Seal presses and related tools can support consistent marking on paperwork or packaging when embossing is part of your workflow, and they help teams apply a repeatable mark that is easy to recognize later. Most importantly, keep records that match your handoffs. A seal log should include the seal number, date and time, who applied it, and who verified it at the next checkpoint. If something looks wrong, staff should follow a clear response such as pausing acceptance, taking photos, and reporting the issue right away.

To Sum Up

Choosing a security seal is simpler when you treat it as a matching problem. Start with the shipment type and the access point. Pick a strength level that fits the risk and likely attack method. Choose a style that works with your packaging materials and the conditions the load will face. Then make sure the tamper signal is easy to see and that inspection takes seconds, not minutes.

Finally, remember that seals work best as part of a routine. Consistent placement, clear records, and simple training create the proof you need when a dispute happens. Run a small pilot on two or three shipment types, track how often seals fail during normal handling, and measure how long inspections take at receiving. When the process is easy to follow, teams follow it, and your sealing program becomes a practical part of daily operations instead of a box to check.