At YK Door Industry Co., Ltd., a trusted UL fire door supplier, we understand the critical importance of incorporating fire-rated door assemblies into modern buildings. These assemblies serve as a primary barrier against fire and smoke, preserving life and minimizing property loss during emergencies.

A UL fire resistance door is not a standalone product—it comprises an integrated system of door, frame, glazing, and hardware, all designed to function cohesively as one tested unit. While components are typically evaluated separately by certified laboratories, certain configurations require combined testing to maintain a consistent UL fire rating.

Therefore, only pre-approved combinations should be installed to ensure code compliance and certified performance.

Fire Rated Door Testing Standards

Fire-rated assemblies must pass stringent testing protocols such as:

- UL 10B – Fire Tests of Door Assemblies (neutral or negative pressure)

- UL 10C – Positive Pressure Fire Tests of Door Assemblies

- NFPA 252 – Standard Methods of Fire Tests of Door Assemblies

These tests evaluate both fire endurance and resistance to impact and water pressure through a hose stream test. It’s worth noting that many U.S. building codes exempt 20-minute rated doors from the hose stream test, recognizing their use in less critical fire zones.

Today, regulations under the International Building Code (IBC) require side-hinged fire doors to undergo positive pressure testing, as found in UL 10C and NFPA 252. This adjustment reflects real-world fire behavior more accurately and ensures doors can withstand intense, pressure-driven heat scenarios.

Essential Requirements for steel fire rated doors

YK’s UL listed fire doors meet or exceed international standards and include the following core specifications:

- Fire ratings range from 20 to 180 minutes, certified by independent third-party labs and clearly labeled.

- Assemblies must comply with NFPA 80, NFPA 101, the IBC, and the International Fire Code (IFC).

- All fire doors must be self-closing and feature positive latching mechanisms.

- The fire rating of the wall in which the door is installed determines the minimum fire resistance rating required for the door.

Performance Factors of UL Fire Rated Door Assemblies.

Fire Endurance

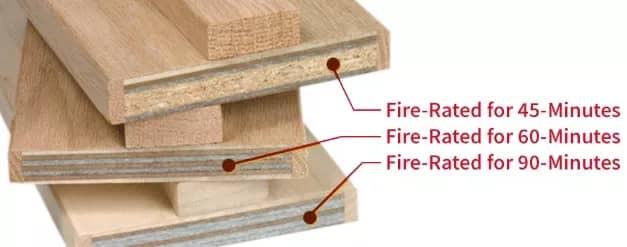

At YK Door Industry Co., Ltd., our UL steel fire rated doors are engineered and rigorously tested for endurance under extreme heat. During certification, the door assembly is exposed to temperatures reaching 1,925°F (1,052°C) for up to 180 minutes. A successful UL fire resistance door must remain securely in its frame, resist through-openings, and prevent flame passage throughout the test duration. Based on performance, the doors are certified for 20, 45, 60, 90, or 180-minute ratings.

Hose Stream Test

Immediately following the fire exposure, doors undergo the hose stream test, in which pressurized water—delivered at 30 psi from 20 feet—is used to simulate the structural stress caused by fire-fighting efforts. This test ensures the integrity and resilience of UL fire rated door assemblies. It’s important to note that 20-minute fire doors are typically exempt from this specific test under most U.S. building codes.

Temperature Rise steel fire rated doors

Beyond containing flames, many fire doors—especially in stairwells or high-traffic escape routes—are designed to limit the transfer of radiant heat to allow safe evacuation. Known as temperature rise fire doors, these products bear an additional rating of 250°F, 450°F, or 650°F, indicating the maximum heat increase on the non-fire side within 30 minutes. A 250°F UL fire door is the most stringent and is often specified in critical life-safety applications.

Smoke and Draft Control

In corridor and barrier systems, especially in healthcare and hospitality settings, UL fire rated doors with smoke seals are essential. Doors rated for smoke and draft control undergo testing per UL 1784, which evaluates air leakage and ensures that the door assembly restricts smoke migration during early fire stages. At YK, we offer 20-minute UL smoke-rated fire doors ideal for these specialized applications.

Glazing in UL Fire Rated Glass Doors

Modern architecture often demands transparency, even in fire-protected areas. UL fire rated glass doors from YK incorporate certified glazing that not only preserves visibility but also contributes to safety, aesthetics, and operational efficiency. Vision panels help first responders assess interior conditions during emergencies, improving response time and decision-making.

However, incorporating glazing into UL fire door assemblies introduces additional compliance layers. All glazing components must meet both fire endurance and impact resistance standards—particularly in high-occupancy facilities like schools, hospitals, and public buildings.

Impact Safety and the Evolution of Fire Rated Glazing

Historically, wired glass dominated the market as the go-to fire-resistant glazing. While it appeared strong due to embedded wires, extensive testing revealed that traditional wired glass lacks sufficient impact strength. It fractures easily and poses injury risks during human contact, failing to meet the modern CPSC 16 CFR 1201 safety standards.

In response, U.S. building codes began phasing out exemptions. As of the 2003 International Building Code (IBC), traditional wired glass is no longer permitted in educational and athletic facilities unless it meets Category I or II impact safety requirements:

- Category I (150 ft-lbs): for glazing up to 1,296 in²

- Category II (400 ft-lbs): for larger or high-impact zones

UL Double Leaf Steel Fire Door

At YK Door Industry, all UL fire rated glass doors are produced with safety glazing that meets or exceeds these benchmarks, ensuring compliance in both new construction and retrofits.