This cooling tower Malaysia maintenance checklist reveals everything plant managers must know in 2025 to avoid costly repairs and extend equipment life.

How long has it been since you last checked your cooling tower? Cooling towers are essential in Malaysia’s industrial sector, playing a critical role in regulating heat for many plant operations. Yet, despite their importance, these systems are often overlooked, leading to inefficiencies, higher costs, and potential compliance issues.

Given Malaysia’s humid, tropical climate, regular maintenance isn’t just a good practice; it’s a necessity. The constant battle with algae growth, mineral scaling, and water quality poses unique challenges that demand a solid maintenance regime.

To help you get the most out of your cooling tower Malaysia, we’ve created this step-by-step maintenance checklist. Whether you’re dealing with the humid climate of Malaysia or navigating industrial cooling systems elsewhere, this guide will ensure your cooling systems remain efficient, cost-effective, and compliant.

Importance of Cooling Tower Maintenance in Malaysia

Your cooling tower is more than just an industrial installation; it’s the backbone for maintaining heat regulation across your plant. Regular service cooling tower inspection in Malaysia comes with numerous benefits, especially for industrial applications, including:

- Ensuring Efficiency and Longevity: By conducting regular checks, you reduce the chances of costly breakdowns and downtime. This is vital for power plants, education industries, and larger installations where consistent operational efficiency is critical.

- Reducing Operational Costs: Preventative measures such as cleaning and inspecting parts can significantly lower energy consumption, supporting system optimization and lowering operational costs.

- Unique Climate Challenges: Humidity contributes to excessive algae growth.

- Avoiding Costly Consequences: A poorly maintained cooling tower directly results in energy loss, degraded efficient cooling capacity, and eventual system failure.

By dedicating time to proper maintenance, you’ll save on long-term costs, improve safety, and ensure compliance with governmental standards.

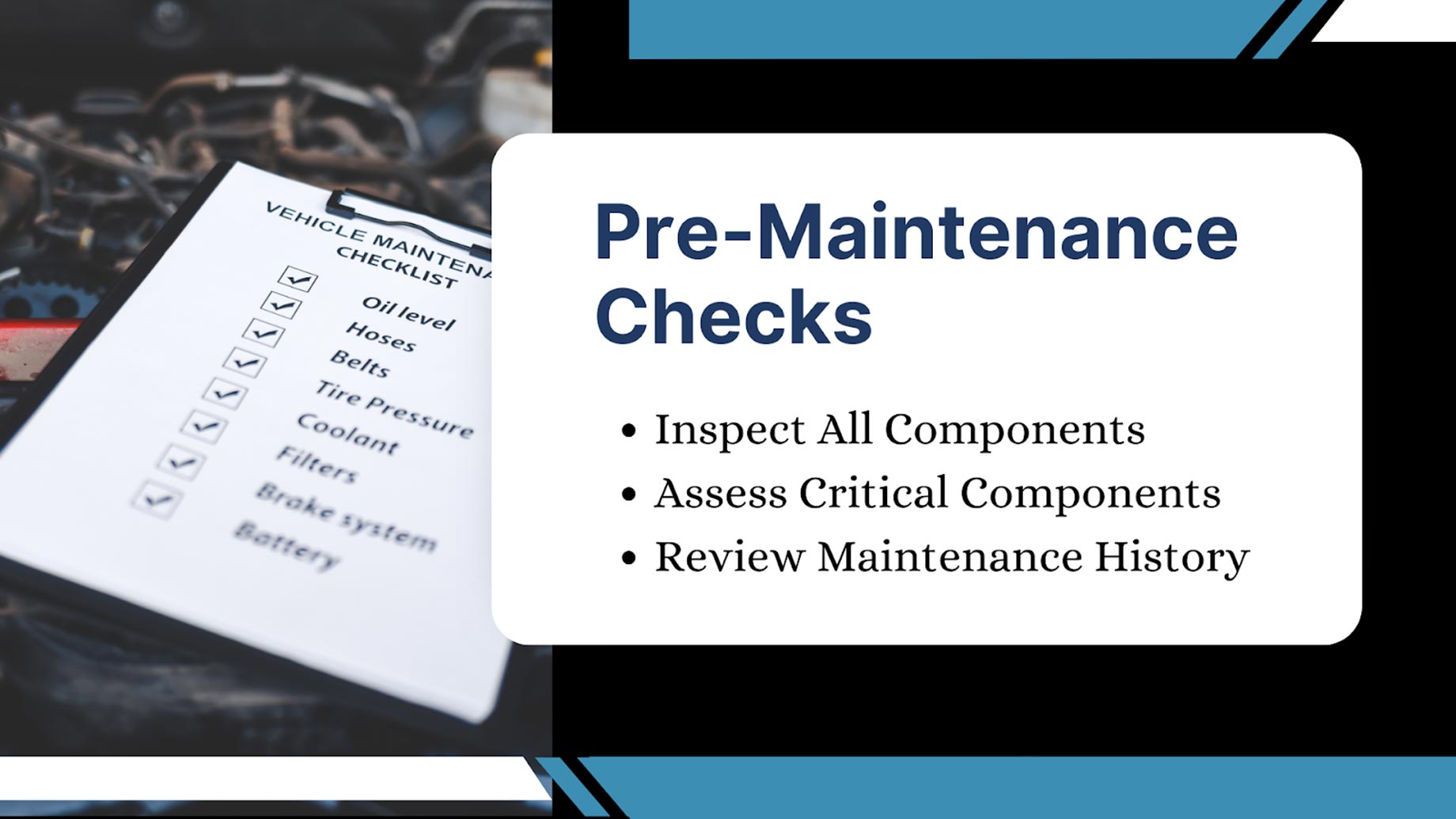

Pre-Maintenance Checks

Before you begin, always start with a thorough routine inspection. Here’s what to focus on:

- Inspect All Components: Examine fan blades, motors, basins, and water distribution systems for damage or wear.

- Assess Critical Components: Make sure drift eliminators, fill materials, and nozzles are working as they should to keep your system operating at optimal condition.

- Review Maintenance History: Check maintenance records to ensure schedules align with recommended standards and address any overdue tasks.

Weekly Maintenance Checklist

Weekly upkeep keeps your cooling tower running smoothly, supporting efficient heat transfer and optimal temperature control:

- Regularly inspect and maintain mechanical parts like motors and fans to keep everything running smoothly.

- Lubricate all moving components to minimize wear and extend their lifespan.

- Check and adjust belt tension, replacing any worn or damaged belts to avoid slippage and breakdowns.

- Inspect the fill material to prevent scaling.

- Align and balance fan blades to reduce vibrations, boost efficiency, and improve performance.

- Look out for visible leaks, unusual noises, or vibrations that could signal underlying issues.

Monthly Cooling Tower Maintenance Tasks

Performing a regular monthly inspection of your cooling tower is essential to ensure its efficiency, longevity, and overall health. Follow these step-by-step guidelines for a thorough inspection:

- Assess the overall condition of the tower casing for signs of wear or damage.

- Check the cold water basin for clarity and cleanliness. Remove any debris or sediment to maintain optimal water quality.

- Inspect the fill material for scaling, clogging, or any damage that may reduce efficiency.

- Clean sump screens to prevent debris from entering the system.

- Check the water levels in the basin and make necessary adjustments to maintain the ideal level. Ensure control valves are functioning properly and inspect for any signs of corrosion or damage.

- Ensure all ladders, walkways, and fan decks are in good condition for safe maintenance access.

- Apply proper lubrication to fan motors, bearings, and water distribution system components to ensure smooth operation. Check for excessive wear or overheating in moving parts.

- Monitor the electricity consumption of fan motors to identify any unusual increases in energy usage.

- Inspect gearboxes and drive systems for smooth operation and proper alignment.

Quarterly Maintenance Checklist

Regular system checkups are key to ensuring everything runs smoothly. Take a moment every few months to check your system. Quarterly reviews are essential for process cooling applications, especially under rigorous demands:

- Conduct a detailed inspection of the cooling tower’s exterior, checking structural integrity, fan blades, and louvers.

- Inspect fan motors, belts, alignment, and bearings, and lubricate as needed.

- Clean drift eliminators, nozzles, and water strainers or filters to ensure peak performance.

- Test water quality parameters like pH, conductivity, and TDS, and verify the treatment system is functioning effectively.

- Inspect gearbox oil levels and condition, lubricating where required.

- Confirm the safety and integrity of access platforms and safety rails for secure maintenance operations.

Annual Preventive Maintenance Must-Haves

- Perform a comprehensive mechanical inspection of components like gearboxes, driveshafts, and fan blades.

- Inspect for signs of corrosion, especially in FRP (fiberglass reinforced plastic) or metal structures.

- Rebalance and calibrate your system controls for optimal operation.

- Conduct thermal performance testing to ensure the system runs efficiently.

Water Treatment A Critical Maintenance Priority

Proper water quality is essential for the efficiency and longevity of cooling towers. Without it, issues like algae growth, biofilm buildup, mineral scaling, and corrosion can reduce efficiency, increase energy costs, and shorten equipment lifespan. Neglecting water treatment also raises the risk of legionella outbreaks, which can pose serious health risks from contaminated water vapor.

Regular chemical dosing, biocides, and automated controllers help maintain balanced water chemistry, eliminate harmful microorganisms, and ensure consistent performance. Partnering with a professional water treatment company can provide customized solutions, routine testing, and expert guidance tailored to your system’s needs.

Energy Efficiency and Performance Monitoring Tips

- Install smart sensors and flow meters to track cooling output vs. energy input and identify inefficiencies in real time.

- Use predictive maintenance tools to identify potential issues before they escalate, reducing downtime and energy waste.

- Consider tools or software popular in Malaysia, such as IoT-based monitoring systems, to streamline and automate performance tracking.

- Optimize your cooling system by scheduling regular cleaning of filters, coils, and vents to maintain peak performance.

- Train staff to understand energy-saving practices and ensure proper operation of cooling equipment.

- Explore alternative cooling strategies, like heat recovery systems or thermal insulation, to improve overall energy efficiency.

Regulatory Compliance in Malaysia (2025 Update)

Regulatory pressures in Malaysia are rising due to increased government oversight, stricter compliance requirements across industries, and efforts to ensure transparency and accountability in business practices. These measures aim to address emerging challenges such as financial misconduct, data privacy concerns, and environmental sustainability.. Here’s what to consider:

- Ensure water usage aligns with national standards or green building requirements. Regularly monitor water usage to identify inefficiencies and implement water-saving technologies like low-flow fixtures or rainwater harvesting systems to meet these standards.

- Stay updated on Department of Environment (DOE) or Malaysian Green Technology Corporation (MGTC) standards. Subscribe to newsletters or join relevant industry groups to stay informed about policy changes, incentives for green initiatives, or new compliance requirements.

- Proper documentation helps avoid penalties during unexpected audits or inspections. Maintain detailed records of water usage, maintenance logs, and compliance reports. Conduct periodic internal audits to ensure all documents are accurate and readily accessible.

Concluding Thoughts

By implementing this comprehensive maintenance checklist tailored for cooling tower Malaysia operations, you can enhance your system’s performance, reduce costs, and ensure compliance. Regular, climate-aware maintenance is the secret to long-term success.

If you’re unsure where to begin, or need expert support, our local technicians at ICS are ready to help you audit and optimize your current cooling systems. Get in touch, and we’ll ensure your operations run with peak efficiency in 2025 and beyond.