3D printing is no longer just a prototyping tool—it’s a full-fledged production solution. From automotive components to outdoor signage, industries now demand materials that perform well not just in the lab, but in the real world, under pressure, and across the elements. One material that has steadily gained attention for these rugged applications is BigRep ASA—an industrial-grade 3D printing filament built to deliver outstanding performance, even in the harshest conditions.

Whether you’re printing prototypes for field testing or functional end-use parts exposed to UV rays and moisture, BigRep ASA is engineered to meet the challenge. Let’s explore what makes this ASA filament the go-to choice for high-performance, weatherproof parts.

Key Material Properties

One of the standout features of BigRep ASA is its resistance to ultraviolet light. While materials like ABS can fade and become brittle under prolonged exposure to the sun, BigRep ASA retains both its mechanical properties and appearance. This makes it particularly well-suited for outdoor applications, such as equipment enclosures, signage, and fixtures.

Water and Weather Resistance

BigRep ASA isn’t just sun-proof—it’s also rain-proof. It can endure prolonged exposure to moisture and humidity without warping, swelling, or losing integrity. This weather resistance is critical in industries like construction or agriculture, where parts often need to perform in unpredictable outdoor environments.

Mechanical Strength

In terms of mechanical performance, BigRep ASA holds its own against more traditional engineering plastics. It offers excellent impact resistance and a high degree of rigidity, allowing parts to maintain their shape and function under stress. This makes it suitable for both moving and structural parts that experience mechanical loading.

Chemical Resistance

BigRep ASA is resistant to a range of chemicals, including oils, greases, and cleaning agents. This opens up possibilities in industrial environments where chemical exposure is a regular occurrence, such as automotive workshops or factory floors.

Thermal Resistance

With a heat deflection temperature above 95°C, BigRep ASA is capable of withstanding higher temperatures than PLA or PETG. It won’t deform in the backseat of a car on a hot summer day or in high-friction applications that generate heat.

Printing Performance

Despite being a high-performance material, BigRep ASA is surprisingly user-friendly. It exhibits low warping, minimal shrinkage, and strong layer adhesion. These properties make it easier to print large parts successfully without needing an enclosure or excessive print bed modifications.

BigRep ASA prints with a smooth, matte finish that not only looks professional but also hides layer lines more effectively than glossy materials like ABS or PLA. This makes post-processing optional rather than necessary.

Designed with BigRep’s large-format industrial printers in mind, this ASA filament delivers stable results across wide build volumes. It’s optimized for consistent extrusion, which reduces the risk of print failures in long production runs.

BigRep ASA is compatible with common post-processing techniques. It can be sanded and painted easily, and it bonds well with adhesives for assemblies or hybrid parts. This flexibility makes it ideal for applications where both aesthetics and function matter.

Applications of BigRep ASA

Because of its excellent UV and moisture resistance, BigRep ASA is ideal for signs, kiosks, and exterior-mounted parts. These components can last for years outdoors without fading or cracking.

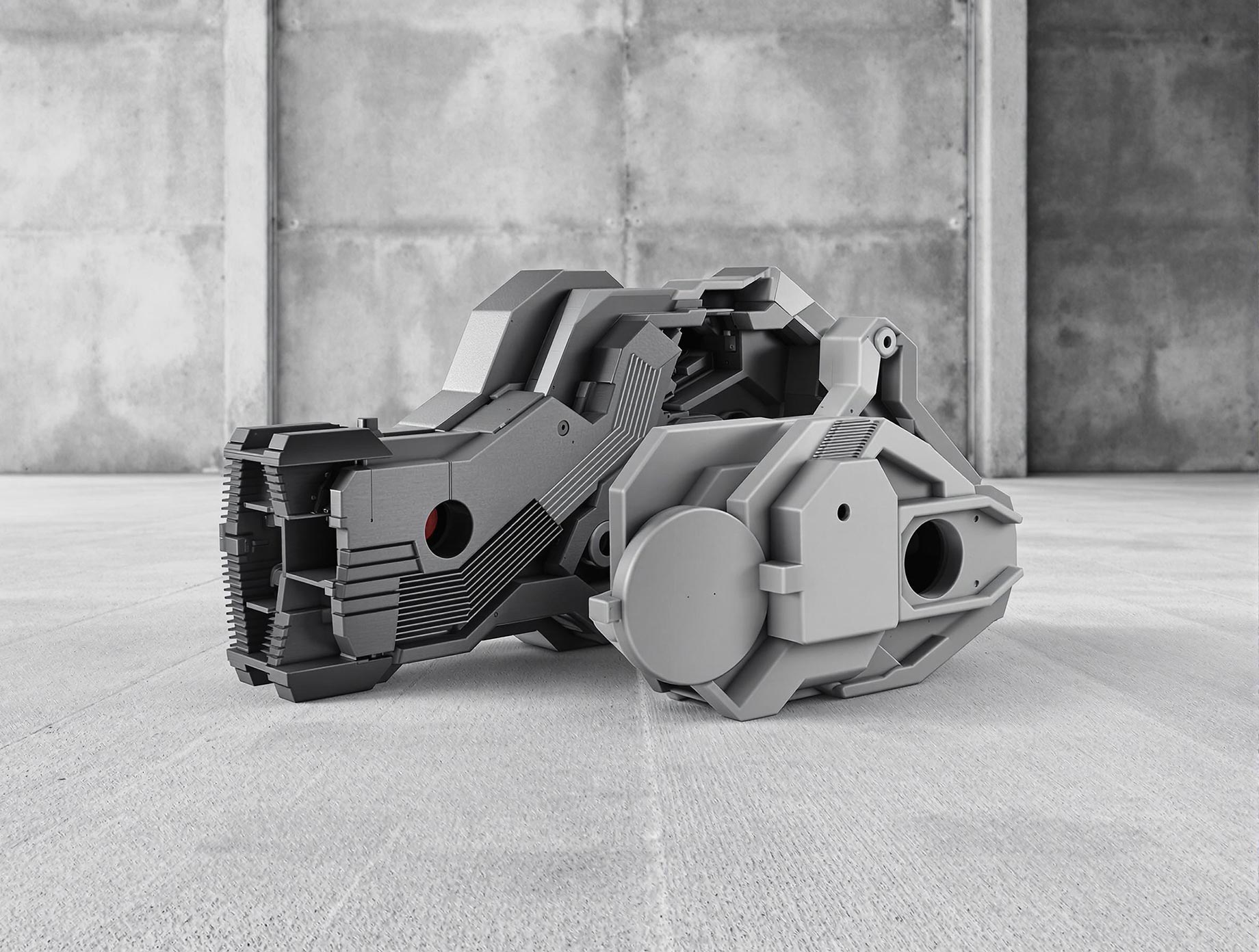

Under-the-hood parts, trim pieces, and custom brackets benefit from the filament’s heat and chemical resistance. BigRep ASA is an excellent substitute for ABS in automotive prototyping and even low-volume production.

On construction sites, 3D printed tools and jigs face a rough life. BigRep ASA can withstand impacts, abrasions, and environmental exposure, making it a smart choice for rugged applications.

Need to test a prototype in the real world? BigRep ASA gives engineers the ability to print functional components that can be field-tested in actual conditions, not just handled in the office.

Because it resists both UV and moisture, BigRep ASA is perfect for electrical casings and housings that need to stay reliable in outdoor or industrial environments.

Comparison to Other Filaments

When choosing the right material for demanding applications, it’s essential to understand how BigRep ASA stacks up against other commonly used 3D printing filaments.

BigRep ASA vs. ABS

Both materials offer strength and heat resistance, but BigRep ASA adds UV stability and better weather resistance, eliminating one of ABS’s most significant weaknesses.

BigRep ASA vs. PETG

PETG is known for being easy to print and water-resistant, but it lacks the UV and thermal stability of ASA. For outdoor or high-heat applications, BigRep ASA wins out.

BigRep ASA vs. PLA

PLA is great for beginners and visual models, but it doesn’t hold up under stress, heat, or exposure to the elements. BigRep ASA is far more durable and functional for real-world applications.

Sustainability and Safety Considerations

BigRep ASA emits fewer volatile organic compounds (VOCs) compared to ABS during printing, which contributes to a safer workspace, especially important in enclosed or poorly ventilated areas.

Its toughness and longevity reduce the need for frequent reprinting or replacement, which not only saves material but also time and labor. That’s a win for both productivity and sustainability.

BigRep as a company has demonstrated a growing commitment to sustainable manufacturing, with a focus on durable materials that reduce lifecycle waste and energy consumption through efficiency.

Conclusion

BigRep ASA brings together the best of both worlds: professional-grade performance and exceptional weather resistance in a filament that’s easy to print and ready for the real world. Its balance of mechanical strength, UV and chemical resistance, and ease of use makes it the ultimate ASA filament for manufacturers and designers who can’t afford to compromise on durability.

Whether you’re building prototypes that must perform in the field or creating final-use parts for outdoor use, BigRep ASA offers the reliability and performance that today’s applications demand. If your next project needs to survive the elements, this is the filament to trust.