The modern workplace is profoundly evolving, driven by unprecedented digital transformation, reshaping how we approach productivity and innovation. The collaborative robots, or “cobots,” are at the forefront of this technological revolution and have rapidly become indispensable assets in today’s dynamic work environments. Unlike traditional automation solutions, these advanced systems are designed to work harmoniously alongside human employees, creating powerful partnerships that amplify capabilities across industries.

Dobot has established itself as a global leader in collaborative robotics, pioneering cutting-edge technology that defines the future of human-robot cooperation. With a commitment to innovation and practical application, DOBOT’s solutions are helping businesses navigate the complexities of digital transformation while maximizing the unique strengths of human workers and robotic systems. As cobots continue transforming modern workplaces, DOBOT’s expertise sets new standards for what these collaborative technologies can achieve.

Understanding Collaborative Robots

Definition and Evolution

Collaborative robots are designed to work safely alongside humans in shared workspaces without protective barriers. The concept emerged in the 1990s when General Motors, UC Berkeley, and Northwestern University researchers developed the first cobots as “programmable constraint machines.” Michael Peshkin and J. Edward Colgate were key figures in this development, with the first cobot patent filed in 1999. Initially created to improve ergonomics without introducing new risks, cobots have evolved dramatically in design and functionality over the past two decades.

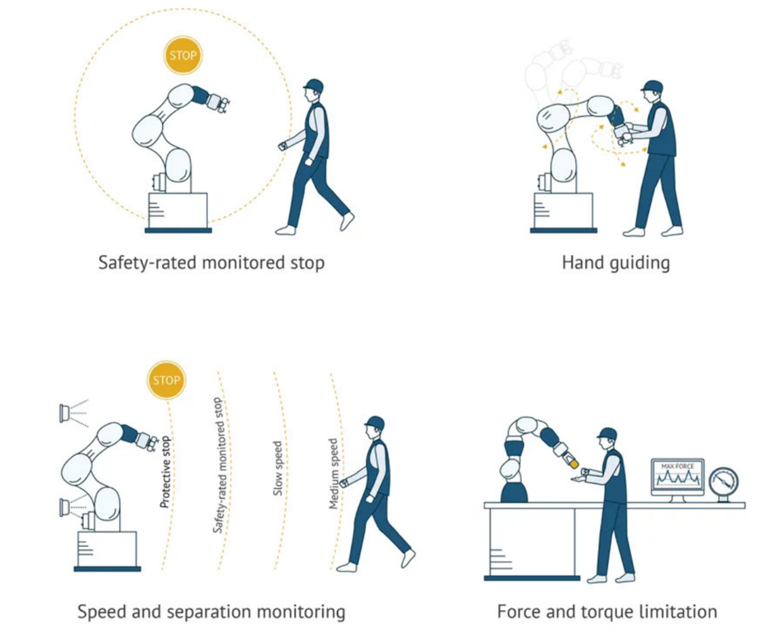

Safety and Human Interaction

Safety features form the core of collaborative robot technology. Unlike traditional industrial robots that operate in isolation, cobots incorporate advanced sensors, force limitation mechanisms, and responsive controls that detect human presence. These robots automatically slow down or stop when someone enters their operational space. This built-in safety architecture allows direct human-robot collaboration without protective fencing, creating more flexible production environments where humans handle complex decision-making. At the same time, cobots perform repetitive or physically demanding tasks.

Technological Advancements in Cobots

Collaborative robots continue to evolve with cutting-edge technologies that enhance their performance and capabilities. AI integration and advanced control systems have transformed cobots from simple assistants into intelligent partners in manufacturing environments.

| Feature | Description |

|---|---|

| Integrated Control and Precision | Modern cobots utilize embedded vision systems for enhanced spatial awareness and sub-millimeter precision. These systems enable intricate tasks while adjusting grip strength through haptic feedback. |

| Advanced Safety Technologies | Today’s cobots incorporate multi-layered safety systems with dynamic zones that respond to human proximity. They feature programmable parameters that maintain protection while optimizing productivity. |

| Ease of Deployment and Programming | Collaborative robots offer intuitive programming through hand-guiding and pre-programmed application packages, allowing for quick redeployment in under 60 minutes compared to days for traditional robots. |

Impact on the Workforce: Replacement or Enhancement?

Collaborative robots transform workplace dynamics by creating new relationships between humans and machines. Instead of replacing workers, evidence suggests cobots primarily enhance human capabilities and reshape job responsibilities.

Task Automation vs. Human Oversight

Cobots excel at taking over repetitive, dangerous, and monotonous tasks in the workplace. This redistribution allows employees to focus on work requiring creativity, problem-solving, and interpersonal communication skills, where humans outperform machines. Studies confirm that cobots increase productivity while reducing workplace injuries by handling physically demanding tasks. The partnership creates a more flexible workflow as cobots learn from human operators and adapt to changing production conditions.

Case Examples and Industry Insights

Manufacturing facilities using collaborative robots report significant productivity and employee satisfaction improvements. In assembly operations, cobots handle precise component placement while workers manage quality control and process improvements, resulting in 35% productivity gains. Automotive plants use cobots for dangerous welding tasks, eliminating injury risks while workers oversee operations and program adjustments. Healthcare facilities employ collaborative robots for medication dispensing and supply transport, freeing medical staff to concentrate on patient care and complex decision-making.

DOBOT’s Role in Shaping the Future of Work

DOBOT Robotics stands at the forefront of the collaborative robotics revolution, transforming how businesses approach automation and workforce development. Their innovations bridge the gap between traditional industrial robots and human workers, creating more productive manufacturing environments.

Company Overview and Global Reach

Founded in 2015, DOBOT quickly became a leading provider of collaborative robots worldwide. The company operates branches and R&D centers across 12 countries, including the United States, Germany, Thailand, and Japan. As China’s top collaborative robot exporter, DOBOT has deployed over 72,000 cobots globally, extending its automation solutions to more than 80 countries and regions.

Product Portfolio and Innovations

DOBOT offers a comprehensive range of collaborative robots for various applications and industries. Their product lineup includes the sophisticated CRA, CR, and CRS series, alongside specialized models like MG400, M1 Pro, Nova, and Magician. Each model addresses specific automation needs, from desktop-grade precision tasks to industrial-scale operations, providing businesses with flexible automation options regardless of size or technical requirements.

Cross-Industry Applications

DOBOT’s Collaborative Robots: Applications

• Adapt to diverse automation challenges across industries

• Manufacturing: Precise assembly with consistent accuracy

• Healthcare: Laboratory and medical supply automation

• Education: User-friendly teaching tools for robotics

• Versatile and cost-effective automation solution for businesses

Enhancing Human Capabilities Through Cobots

Collaborative robots (cobots) work alongside humans to combine their strengths. These specialized machines augment human capabilities rather than replace workers, creating a more productive manufacturing environment.

| Aspect | Summary |

|---|---|

| Safety and Productivity | Cobots operate with advanced safety features, including instant braking systems and sensor fusion technologies that create protective envelopes around workspaces. These systems enable humans and machines to work together without traditional barriers while maintaining operational efficiency. |

| Task Distribution | Cobots handle repetitive, demanding, or hazardous tasks while humans focus on complex problem-solving and creativity, creating a complementary relationship. This distribution boosts productivity by up to 35%, reducing workplace injuries and improving employee job satisfaction. |

| Collaborative Work Environments | Modern workspaces blend human cognition with cobot precision through intuitive interfaces that require minimal technical expertise. This proximity fosters faster communication and problem resolution while increasing employee engagement as workers transition to oversight roles. |

| Future Trends and Integration | Advanced cobots integrated with AI will anticipate worker needs through adaptive learning algorithms as deployment expands beyond manufacturing. As capabilities increase and costs decrease, small and medium businesses will gain greater access to this transformative technology across diverse industries. |

Conclusion

Collaborative robots have revolutionized manufacturing by complementing human workers with advanced safety features and intuitive programming. DOBOT’s successful deployment of over 72,000 cobots worldwide has demonstrated this. These cobots deliver significant productivity gains while democratizing automation technology for businesses of all sizes.